What is Lockout Tagout?

Such a broad and specific question at the same time, isn’t it?

Lockout tagout is the de-energizing and securing of equipment, machinery, or processes so hazardous energy isn’t re-introduced during servicing or repair. This includes closing electrical circuits and valves, neutralizing extreme temperatures, securing moving parts, and more.

But safety professionals know, this simple lockout tagout definition only scratches the surface.

A Brief History of LOTO

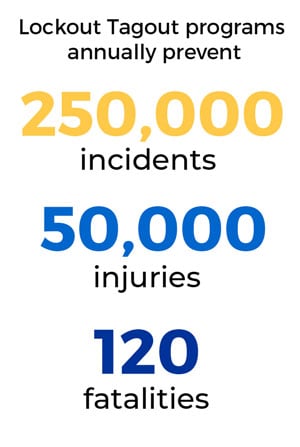

The OSHA lockout tagout standard for the Control of Hazardous Energy (Lockout/Tagout), Title 29 Code of Federal Regulations (CFR) Part 1910.147, was developed in 1982 by the United States Occupational Safety and Health Administration (OSHA) to help protect workers who routinely service equipment in the workplace. Legally, it went into effect in 1989. Ever since, the lockout standard has played a vital role in keeping employees safe on the job. Key lockout tagout statistics demonstrate that lockout programs:

- Save lives by preventing an estimated 50,000 lockout tagout injuries and 120 fatalities annually[1]

- Cut costs by decreasing lost employee time and insurance costs

- Improve productivity by reducing equipment downtime

OSHA provides tips and resources on workplace lockout tagout requirements and safety, including an overview(opens in a new tab) and fact sheetPDF (opens in a new tab) .

What is the difference between lockout and tagout?

While often intermingled, the terms “lockout” and “tagout” are not interchangeable.

Lockout

Lockout occurs when an energy source (electrical, mechanical, hydraulic, pneumatic, chemical, thermal, or other) is physically isolated from the system that uses it (a machine, equipment, or process). This is done using a variety of lockout padlocks and devices best suited for specific applications. Devices such as circuit breaker lockouts or valve lockouts can be used for more specific lockout jobs.

Tagout

Tagout is the process of affixing a label, or tag, that communicates information about what’s being done to the machine or equipment and why it’s important. Details on a tag may include:

- DANGER or WARNING lockout tag

- Instructions (e.g., Do Not Operate)

- Purpose (e.g., Equipment Maintenance)

- Timing

- Name and / or photo of the authorized worker

Tagout alone is not recommended as it does not provide a physical means to prevent equipment from re-energizing. Since the inception of the lockout tagout standard in 1989, energy isolation points have been modified or replaced to allow for safety padlock placement, and new devices have been developed to retrofit energy sources to help meet the standard.

When used together by affixing a tag to a padlock, lockout and tagout provide enhanced protection for workers against re-energization.

Lockout tagout program components and considerations

Elements and compliance

A typical lockout program can contain more than 80 separate elements. To have an OSHA-compliant lockout tagout program you must include:

- Lockout tagout standards, including creating, maintaining and updating equipment lists and hierarchies

- Task-specific procedures

- Workplace regulations, such as confined space entry requirements

Lockout tagout best practices

Periodic inspections are required. As a best practice, an annual review of lockout procedures is recommended. Other best practices include:

- Program standardization

- Lockout tagout software

- Annual authorized / affected training (authorized will be more frequent)

- Updating isolation points

- Management of change

- Contractor training

- Device inventory

Coordinating with on-site contractors

The host employer often will have greater familiarity with the energy control procedures used at the host facility. However, according to 29 CFR §1910.147(f)(2)(i), the host and contract employers are required to inform each other about their respective energy control procedures.[2] Such coordination is necessary to ensure that both sets of employees will be protected from hazardous energy.

The contractor must take the reasonable lockout tagout steps, consistent with its authority, to protect its employees if the contractor knows, or has reason to know, that the host’s energy control procedures are deficient or otherwise insufficient to provide the requisite protection to its employees.

Written procedures for powerlifting equipment and docks

In standard shipping and receiving areas or docks, you will need machine-specific written procedures for:

- Dock levelers and locks

- Battery chargers

- Palletizers

- Cranes

- Hoists

- Anything hard-wired to an electrical panel

Construction and agriculture – separate but similar

Construction has its own code of regulations, so it is not covered in general industry. Agriculture CFR 1928 doesn’t have any mention of lockout tagout, but the NIOSH-backed National Ag Safety Database has lockout program recommendations. All the steps follow OSHA 1910.147.

If implementing a program for agriculture, look at all the equipment in the facility and identify isolation points for each piece of equipment. Create procedures and procure locks, devices and tags to isolate the equipment during servicing. Train your authorized employees on when, how and why they need to lock out while servicing equipment.

1910.147 minor servicing clause

OSHA has additional guidance around the minor servicing clause(opens in a new tab), which is an exception to the lockout tagout standard. Three specific criteria must be met for this clause to apply:

- Occur during normal production operations

- Be routine, repetitive and integral

- Use alternative measures to provide effective protection from the hazardous energy

Paperwork requirements for group, complex or simultaneous operations

Lockout tagout requirements for paperwork vary by company. However, a best practice is to have a log of all servicing that requires lockout with sign-out sheets of all isolation devices. Any permits needed to complete the service (hot work, confined space or working at heights) should be copied and kept with the service log. Keeping devices and documentation together is a best practice, usually achieved through use of a permit control station.

Understanding lockout tagout procedure requirements

Grouping similar machines

OSHA allows the grouping of same or similar equipment and procedures to ease the burden of periodic inspections. A best practice is to have a specific procedure for each individual machine posted on or near the machine. Even if you have two identical machines, it's still preferred to have a procedure for both. This helps prevent confusion and demonstrates your thoroughness to inspectors.

Some companies develop generic lockout tagout procedures and supplement them with checklists or appendices to address various, distinct equipment as part of their lockout system. This type of procedure may be considered a single energy control procedure (instead of multiple procedures) for inspection purposes if all of the criteria for grouping same or similar equipment is met. However, if checklists or appendices address equipment that does not all use the same or similar types of control measures, the employer is required to divide machinery and equipment into groups based on the same or similar types of control measures.

Once this is accomplished, an employer may inspect and review the generic energy control procedure in conjunction with each distinct group of equipment referenced in the relevant checklists or appendices.

Machine-specific lockout procedures for contracted work

You need machine-specific procedures for all equipment at your facility, even if contractors are the only people authorized to work on the equipment. Further, even if there are no authorized employees, training is required for all employees and a periodic (best practice: annual) procedure review needs to be complete, with any changes communicated to the contractors before servicing.

Equipment exempt from lockout procedures

To be exempt, equipment must meet all eight criteria from 1910.147 (c)(4)(i): [2]

- No stored or residual energy

- Single source readily identified and isolated

- Single isolation point must de-energize to zero energy state

- Lockout is performed for that point

- Single lockout device

- Exclusive control of authorized employee

- No hazards to affected employees

- No accidents involving the equipment

Exempt equipment that has a single energy source

This is typically all plug-and-play equipment, such as laptops, office equipment, fans, power tools, portable equipment and anything that is hardwired and easily isolated with a single power cord or isolation point. Lockout tagout must still be followed, but you do not need a written procedure.

Contractor-written procedures

Authorized contractors can write machine-specific procedures, though these procedures are best developed by employees familiar with the facility to ensure the correct disconnect is being used. Outside contractors unfamiliar with the equipment may miss an energy source if the authorized employees are not involved in verifying the procedures achieve a zero-energy state.

Exceptions and best practices for lockout tagout applications

Temporary removal of lockout or tagout device

Exceptions where a zero-energy state cannot be achieved due to the task at hand are covered under OSHA 1910.147(f)(1).[2] When lockout or tagout devices must be temporarily removed from the energy isolating device and the equipment energized to test or position the equipment, the following lockout tagout steps shall be followed:

- Clear the machine or equipment of tools and materials in accordance with paragraph (f)(1)(i) of this section

- Remove employees from the machine or equipment area in accordance with paragraph (f)(1)(ii) of this section

- Remove the lockout or tagout devices as specified in paragraph (f)(1)(iii) of this section

- Energize and proceed with testing or positioning (f)(1)(iv)

- De-energize all systems and reapply energy control measures in accordance with paragraph (f)(1)(v) of this section to continue the servicing and/or maintenance

Cross-shift and personnel transition

Generally, the transfer of responsibility can be accomplished by the incoming shift accepting control of a system prior to the outgoing employees releasing control of that system. The orderly transfer of personal lockout tagout devices between outgoing and incoming employees must ensure there is no gap in coverage between the outgoing employees’ removal of lockout devices and the incoming employees’ attachment of devices.

Do not substitute workers for devices during an active lockout

The OSHA standard specifies only mechanical devices and tags must be used. For example, an authorized employee watching a switch in place of a device while another authorized worker performs equipment maintenance is not allowed. While convenient, OSHA specifically indicates a method such as this is not as reliable as a mechanical device.

Verifying a zero-energy state

Testing electrical components with a meter is recommended to verify isolation when testing at the control panel is not possible. There are a few ways to verify pressure has been bled out. Noise is a common practice for compressed air lines since dump valves make a loud noise when releasing pressure. Depending on the location of the isolation point, connecting air tools to the line to bleed off the line is another way to verify de-energization.

Lockout device calculator

Estimate the number of devices needed on a per-facility basis

The total number of lockout devices needed for your lockout tagout system will vary by organization. Here’s one way to determine a good estimate for your organization:

-

Decide how many stations or departments need a lockout device cabinet or board.

-

Discuss with authorized employees where the cabinet or board should be located based on the location of equipment, with high-volume equipment areas being the key factor for lockout tagout station placement.

-

Look at the high-hazard equipment areas (boiler, chiller, generators and facilities equipment rooms) and production departments. Count the total number of devices required for all the written machine-specific procedures in the desired area and order 10% of the total number of devices. If the boiler room has 50 pieces of equipment and 100 ball valve devices, the boiler lockout station should have 10 ball valve devices. The need to lock out all equipment at your facility should never happen, but placing an initial order of 10% will be a good starting point.

-

Monitor lockout station devices with an inventory list to see if more devices need to be ordered after the initial order.

Lockout training requirements

Sufficient hands-on training documentation

For sufficient lockout training documentation, you need the authorized employee to sign off that the trainee fully understands the equipment and the lockout tagout program.

Lockout tagout training frequency

You must implement lockout training to employees when they are hired, and then they must be retrained if there is a gap in behavior, knowledge or changes to procedures. While not required, it is a best practice to provide training during the annual review of equipment.

Brady offers a lockout Train-the-Trainer Course, as well as additional lockout tagout training opportunities.

Contractor lockout training requirements

Lockout training includes contractors. Any contractor authorized to service equipment must meet your lockout program requirements and be trained on the written program’s procedures. Depending on your written program, contractors may need to perform group lockout with an authorized employee.

Lockout training responsibilities of contractors

The responsibility is shared. The host employer often has greater familiarity with the energy control procedures used at the host facility; however, the standard requires the host and contract employers to inform each other about their respective energy control procedures. This coordination is necessary to ensure both sets of employees are protected from the hazardous energy.

Lockout tagout annual audits

Requirements

The annual periodic inspections must be conducted by an "authorized employee" and contain at least two components:

- An inspection of each energy control procedure

- A review of each employee’s responsibilities under the energy control procedure being inspected

Documentation

Employers must certify, in accordance with §1910.147(c)(6)(ii),[2] that the prescribed periodic inspections have been performed. The certification must specify:

- The machine or equipment on which the energy control procedure was used

- The date of the inspection

- The names of the employee(s) included in the inspection

- The name(s) of the person(s) who performed the inspection

Review vs. audit vs. inspection

Annual review, audit and inspection all refer to the same lockout tagout requirement. They can occur at any time throughout the year.

Second-person verification

A second person who verifies equipment must be authorized and must ensure all employees who maintain that equipment are knowledgeable about the procedure and responsibilities. A second person also needs to document that inspection.

Inspections by machine vs. groupings

Generally, annual inspections must be completed for each machine. However, OSHA does allow an employer to group separate, machine-specific lockout tagout procedures into one procedure for purposes of complying with the lockout tagout standard, as long as the machines or equipment in the group have the same / similar types of control measures. Energy control procedures used fewer than once a year need to be inspected only when used.

Authorized employee participation requirements

The lockout tagout standard does require a procedure being inspected to be reviewed with all authorized employees as part of the periodic inspection (1910.147(c)(6)(i)(C)).

Degree of formality and comprehensiveness

In order to meet the review requirement, the auditor does not have to observe every authorized employee implementing the energy control procedure on the equipment on which they perform servicing / maintenance. Rather, the auditor performing the inspection may observe and talk with a representative number of employees implementing the procedure in order to obtain a reasonable reflection of the servicing / maintenance practices being evaluated.

To supplement this representative inspection sampling approach, additional reviews must still be performed with all authorized employees who are reasonably expected to implement the procedure during the year. Group meetings may be the most effective way to meet the review requirements and to re-establish employee procedure responsibilities and proficiency.

References

- OSHA Fact Sheet – Lockout Tagout. Retrieved October 5, 2021, from OSHA Fact SheetPDF (opens in a new tab).

- 1910.147 - The control of hazardous energy (lockout/tagout). Occupational Safety and Health Administration. (n.d.). Retrieved October 7, 2021, from OSHA Standard(opens in a new tab).