Interconnectivity

Enables Data Analytics

Interconnectivity and data analytics aren’t just nice to have — they have the power to revolutionize your operations.

When you have the right data at your fingertips, you’re able to connect business and process systems, aggregate information across multiple systems, and enable historical trends and advanced data analytics.

And when it comes to the future, you know “good enough” simply won’t be good enough. Many factories are still using pen and paper for data collection needs. By equipping a factory with cutting-edge hardware, connected software, and analytics, companies can gain better levels of insights than ever before.

Interconnectivity and data analytics are at the heart of Intelligent Manufacturing. And they’re vital in helping you drive improvements and automation. They ensure real-time visibility of inventory, WIP, and production throughput while powering tools that provide real-time visibility of the factory floor to help you have better insights into your operations.

What interconnectivity and data analytics means for you

Leverage valuable insights to see what’s coming and take pre-emptive action with Work in Progress Tracking. And update your manual manufacturing systems to modernize your operation and get the up-to-the-moment data you need to rise to the occasion and design the future.

Interconnectivity

Gain new levels of insights and drive real productivity by equipping your factory with hardware and software that seamlessly integrates into your business systems. Move beyond the pen, paper, and spreadsheets, and unlock the potential of real-time data exchange.

Integration

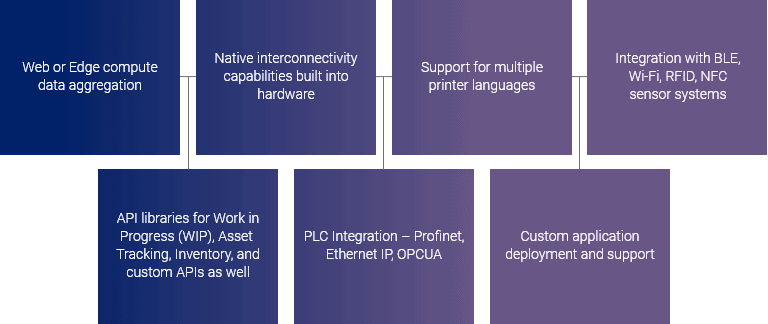

We’ve designed our hardware and software tools specifically for industrial data exchange. By enabling standard industrial control protocols, IoT protocols and standardized API sets, we’re re-inventing the way transaction management is implemented to make it as easy as possible. Whether you’re leveraging our solutions to update your ERP system, or you’re using a cloud-hosted asset management platform – We provide the ability to scale and seamlessly exchange data regardless of your current systems.

The power of integration with Brady

The power of integration with Brady goes beyond just connecting systems. Our vision is to continue to foster the merger of operational technology and informational technology — software talking to hardware — enabling seamless data exchange between more systems and software. This creates a unified ecosystem where data flows freely, providing tangible value to every implementation by unlocking insights, optimizing processes, and driving smarter decision-making across your entire operation.

Seamless integration from a single provider

Bring it all together with Brady's Intelligent Manufacturing Solutions

Enabling data analytics

Connecting data systems is the first step – but the real aha moment is when businesses put that data to work by analyzing it and seeing where real efficiencies and opportunities for improvement are. Having this type of visibility allows you to react faster, reduce downtime, streamline inventory, and manage production orders and assets in real-time. Turn your weekly Excel chart into a dynamic dashboard. Visualize data from SAP, Oracle, or other ERP systems dynamically. Integrate into modern Business Intelligence platforms that help you make the shift from reactive to proactive. All of this is possible when you put your data to work for you.

Build Your Smart Factory Today with Brady

Let’s to discuss what a flexible manufacturing environment can do for you.

Connect with an ExpertHow today’s modern manufacturers are leveraging technology

Centralized Exchange

Integrate all transactional and automated data-input/output systems (e.g. Optical scanning, Printers, Barcode, Optical Character Recognition, RFID).

Leverage centralized API with pre-defined integrations to modern day ERP/MRP systems.

Activity Synchronization

Maximize the effectiveness of engineering changes to the production floor by using technology during the production process for dynamic routing. Understand and accommodate varying environmental factors and how they might impact machines or production processes through virtual build simulation.

Enhanced Productivity

Enhance capabilities with regard to fabrication and assembly, labor efficiency tracking; monitoring worker movements and productivity; and real-time safety monitoring of both workers and equipment.

Environmental

Don’t let things like temperature, humidity, lighting conditions and other operation conditions catch you by surprise. Monitor and resolve key issues before they happen.

Production Intelligence

Use proactive sensing and quality control for detecting defects, predictive maintenance of factory machinery, and tooling life cycle management.

Product Quality

Discrete manufacturing via quality control-based work-in-progress inspections

Quality monitoring of produced goods, machines, and calibration of equipment through the manufacturing process