Automated Data Entry: Benefits, Models, Devices and Systems

Improving efficiency, accuracy and workflow productivity are essential to industrial manufacturers and factories. That’s why so many use proven technology like automated data entry.

This article shows you why you should join the automation revolution, especially with your data collection. It highlights the growing divide between automatic and manual data entry, plus details the seriousness of errors, and their repercussions. Discover the benefits of data entry automation and you’ll never go back to manual data entry.

Automated vs. manual data entry. What’s the difference?

Data is a lifeline for businesses. But how it’s inputted can be vastly different. Two common approaches are through manual entry or by automatic capture.

Manual data entry

This type of data input requires the keying of data by a person. It’s lengthy. It’s inexact. Data bottlenecks and human errors are often the result, which causes problems further down the line.

Automated data entry

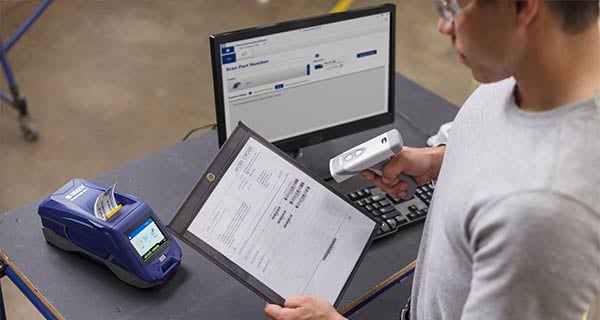

This type of data input eliminates manual steps by having the business and operating systems output the target data in machine-readable formats, like barcodes. It uses data collection tools, such as scanners on the shop floor, to read and input data. Using technology (software, digital hardware, monitoring devices) to capture data instead of manual entry minimizes errors.

Intelligent manufacturing leverages data capture technologies to digitize data entry into computer management systems. When businesses use these digital tools and phase out manual data entry, they benefit from data speed, reliability and reproducibility.

What are the repercussions of data entry errors?

The main drawback of manual entry is that it introduces human error and increases the amount of time to acquire the data and put it into action in your business. The process is so imperfect, it occurs in three stages: entry, verification and correction of data. But errors still slip through, and if you must enter the same data multiple times, the costs of errors compound. You’ll likely see manual data entry cause:

- Misinterpretations

- Miscalculations

- Typos

- Insufficient data

- Inconsistencies

- Duplications

The book "Making Quality Work" introduces the 1-10-100 rule, which asserts that the cost to correct data errors rises exponentially the longer it takes to find them, ultimately impacting efficiency, productivity and accuracy.

It costs $1 to verify data accuracy on entry

It costs $10 to correct an error after the fact

It costs $100 per single error if you do nothing

The 1-10-100 rule is reflected in the amount of money that low-quality data costs organizations – an average of $12.9 million per year (opens in a new tab), according to Gartner, a technical research and consulting firm.

What are the benefits of data entry automation?

Data automation improves data quality, minimizing the cost of low-quality data and the cost of data entry operations. Additionally, automatic data entry happens in real time, benefiting organizations with improvements in:

- Workflows

- Accuracy

- Productivity

- Efficiency

- Decision-making

What are the data automation models?

The strategy or model a business uses to collect data determines how fast and controlled the data capture is. This directly impacts what’s important to a business – the speed, volume and control at which the data is created. There are three ways to capture data:

- A decentralized data capture model is the collection and input of data at many points across an organization. Decentralized data capture offers the advantage of speed and volume, but it lacks control.

- A centralized data capture model is the collection and input of data by a select few. Centralized data capture offers the advantage of control, but it lacks speed and volume.

- A hybrid data capture model is a blended strategy that combines the advantages of decentralized and centralized data automation and eliminates the disadvantages. This method offers scalability and effective quality control.

What types of devices and systems are used in data automation?

An automatic identification and data capture (AIDC) system is a family of automated technologies that capture, identify, verify, transfer or store data. These systems use barcode scanners, RFID readers, sensors and other tools to collect and transfer digital data to equipment controllers and business systems. These business systems can analyze and visualize the data in real time, monitor processes and recommend business decisions.

Common AIDC devices:

Barcode Scanners

Warehouses and manufacturers use barcode scanners to scan barcodes printed on inventory and assets. This facilitates receiving, moving, and picking items. Barcode scanners can be handheld devices used by staff or stationary scanners that capture data as inventory passes by. Software then validates and transmits the data to an inventory database in real time.

RFID

Manufacturers use RFID technology to identify, track, and monitor assets like stock, tools, and even people. RFID tags are read quickly without needing line of sight and are powered by RFID readers. This technology allows for efficient tracking and management of assets throughout the manufacturing process, providing real-time data on location and movement.

Local and enterprise management systems:

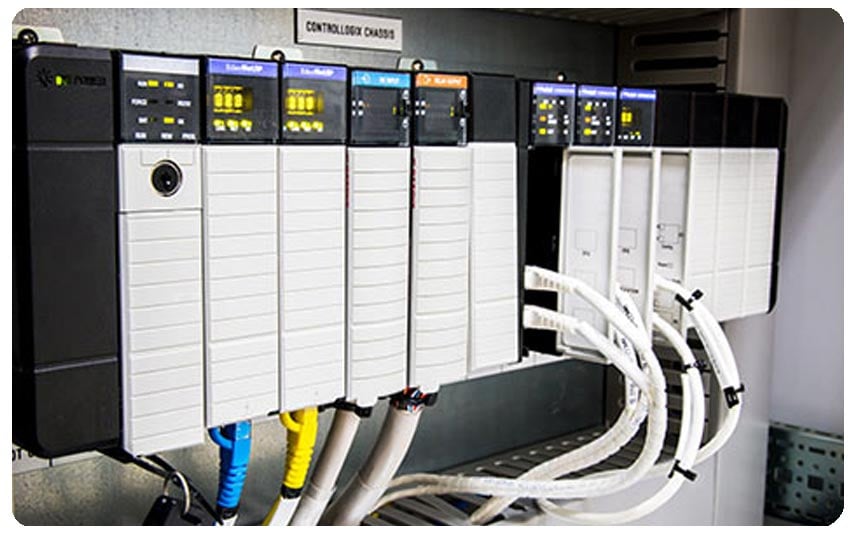

SCADA and PLC

A supervisory control and data acquisition (SCADA) system and programmable logic controller (PLC) device work together to collect data from working machines and motors, monitor equipment and make event-based corrections. SCADA is the software that oversees all the monitors. PLC is the initial, local source of input data and one of the pieces of hardware that the SCADA oversees.

HMI

A human machine interface (HMI) is hardware or software that allows a human operator to monitor, modify or manually override processes. An HMI may be a physical control panel or software that is running on a computer.

Distributed Control System (DCS)

A distributed control system (DCS) supervises complex processes through a system of sensors, controllers and computers that are distributed throughout a plant and communicated with a centralized computer. The DCS collects and analyzes data in real time and adjusts, as needed. When compared to a PLC, which can make local corrections to a single working machine only, a DCS can make multiple adjustments across the plant. When compared to a SCADA, which makes event-based corrections, a DCS uses advanced control techniques to improve process efficiencies throughout the plant.

Remote Terminal Unit (RTU)

A remote terminal unit (RTU) is a device that adds an axis of movement to an articulated robot, allowing it to move up and down a production line. The data that an RTU collects is made available to PLCs and/or HMI, enabling operators to monitor and control robotic assets.

Material Requirements Planning (MRP)

Material requirements planning (MRP) is a stand-alone system that collects data from inventory, the bill of materials and the production schedule to calculate inventory requirements and schedule fabrication or purchase of needed supplies.

Enterprise Resource Planning (ERP)

An enterprise resource planning (ERP) system is a comprehensive software platform that integrates with other business systems to manage day-to-day business operations, such as manufacturing processes, accounting, purchasing, human resources, etc. An ERP may have MRP capabilities, or the two systems may be integrated.

RFID

Manufacturers use RFID technology to identify, track, and monitor assets like stock, tools, and even people. RFID tags are read quickly without needing line of sight and are powered by RFID readers. This technology allows for efficient tracking and management of assets throughout the manufacturing process, providing real-time data on location and movement.

What are big data and big data analytics?

Because a large volume of complex data can be input, sorted, analyzed and shared in real time, data automation facilitates big data and big data analytics, which help businesses to make prompt, informed decisions.

According to McKinsey & Company: “There has been a more than ten-fold increase in data (opens in a new tab) in the last decade and more than a 50 percent increase [in data] in 2020 alone. This brings the current data estimate to a massive 64 zettabytes; a number that continues to grow each day.”

Big data are extremely large and complex volumes of data that arrive at great speed, often from new sources. This explanation is better understood as the “three Vs” of big data, which are:

- Volume: 2.5 quintillion bytes are generated every day (that’s 2,500,000,000,000,000,000 bytes)

- Velocity: data arrives in real time and over time in batches

- Variety: data formats include text, PDFs, video, graphics and other formats

Big data analytics describes the process of examining big data to identify patterns, trends, associations and preferences. The process uses AI technologies, which allow businesses to collect and analyze big data in real time to make instantaneous, knowledgeable decisions about:

- Process improvements

- Predictive maintenance

- Supply chain management

- Production efficiency improvements

- Demand forecast

- Customer service improvements

- Cost management

How is data automation incorporated into intelligent manufacturing initiatives?

Intelligent manufacturing leverages AI and IoT tools to digitize data entry into computer management systems. These digital tools replace manual data entry, and offer the additional benefits of speed, reliability and reproducibility.

How can Brady help automate data capture for industrial or manufacturing applications?

Every business needs a starting point – a place from which everything else flows. For manufacturers and industrial businesses, that starting point is their data input processes that facilitate more efficient, reliable and effective operations.

Begin your data automation journey today with Brady Corporation’s industrial barcode label printers, innovative data capture tools, barcode scanners, RFID readers, labels and tags. Fully automate your label printing process with Brady Workstation Automation Software Suite, a group of apps that facilitates error-free label making.

Always at the forefront of innovation, Brady Corporation anticipates and exceeds our clients’ needs through our unique combination of capabilities, expertise and talent, providing unrivaled solutions whenever and wherever needed.