Direct Thermal vs. Thermal Transfer Label Printers

If you need an industrial label printer, but aren’t sure which type is best for your business, this article is for you.

Though price can influence your decision, it’s the applications you use it for that will ultimately be the deciding factor. For example, do you print labels that need to survive harsh environments and last a long time? Or, do you need temporary identification that will strictly be used indoors?

Two types of printers can handle the majority of industrial tasks – Direct Thermal and Thermal Transfer. Though there are differences, both Direct Thermal and Thermal Transfer are thermal printers. This means they use heat generated by a printhead to print on material.

Unless you’re looking specifically for inkjet or laser capabilities, these two printers, Direct Thermal and Thermal Transfer, are popular, high performing, and save both time and labor.

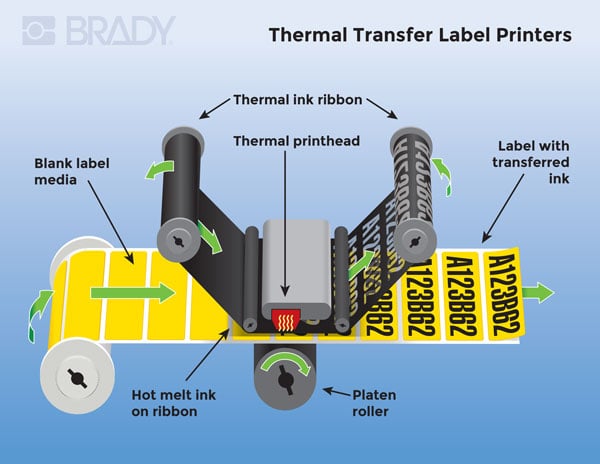

Thermal transfer label printers

How they work

These label printers use a wax- or resin-coated ribbon to transfer ink onto labels when heated.

This printing method uses a ribbon sandwiched between the printhead and the label. When the printhead passes over the ribbon, it heats up the ribbon’s coating, transferring it to the label to create an image.

Key attributes

For long-term applications, Thermal Transfer printers are a great choice. Unmatched for printing quality and durability, these printers produce crisp, accurate, high-definition text, graphics, and barcodes (both 1D and 2D). This printing technology survives harsh conditions like chemicals, UV light, abrasions, moisture, and extreme temperatures.

Applications:

- Hazard Communication Identification

- Asset Tracking

- Barcode Labeling

- Component and Equipment Labeling

- Cryogenic Labeling

- Data and Telecommunications Labeling

- Electrical Labeling

- Exit and Egress Marking

- Facility ID

- Floor Marking

- General ID

- Inventory and Inspection Labeling

- Laboratory Labeling

- Lean and 5S Labeling

- Lockout Tagout

- Pipe and Valve Marking

- Safety ID

- Security ID

- Temperature Indicating Labeling

- Warehouse Marking

- Wire and Cable Labeling

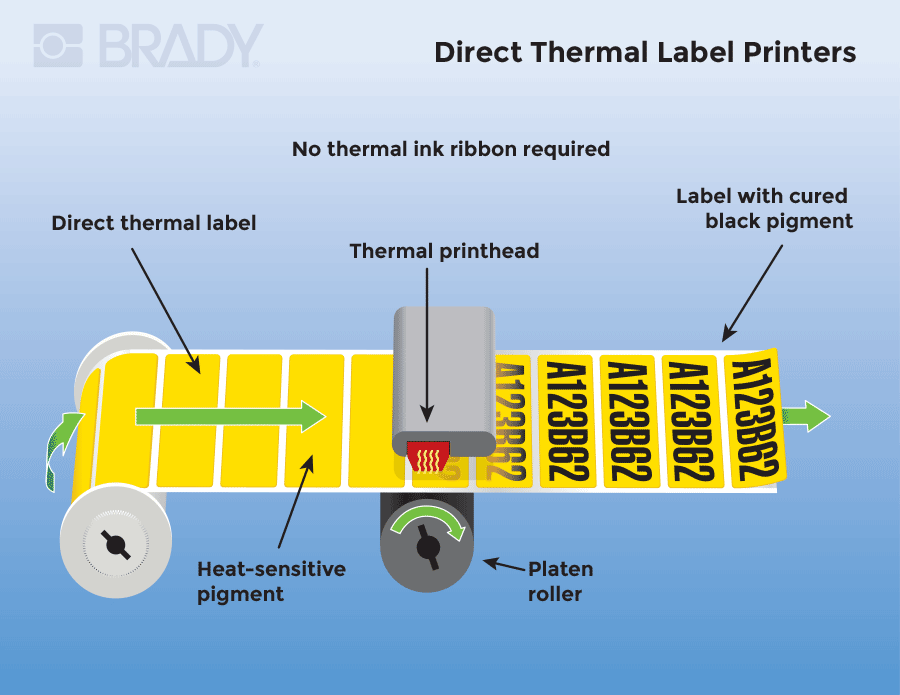

Direct thermal label printers

How they work

These printers use chemically treated labels that darken when heated.

A heated printhead comes in direct contact with labels to produce an image. This simple printing method doesn’t require a ribbon or ink.

Key attributes

For short-term applications (less than 6 months) and one-time use applications, direct thermal printers are ideal. Without ribbons, toners and ink, they are simple to use and produce sharp, quality images that can be read and scanned, such as barcodes. This type of printing performs best indoors and under controlled temperatures.

Applications

- Asset Tracking for Temporary Products

- Barcode Labeling

- General ID

- Government Asset Tracking

- Inventory Labeling

- Name Tags

- Patient Wristbands

- Product ID

- Shipping and Compliance Labels

- Visitor Passes

- Warehouse ID

Similarities and differences: direct thermal vs. thermal transfer

Side by side, here’s a quick comparison to help you select your next printer.

| Thermal Transfer | Direct Thermal | |

|---|---|---|

| Color Printing | ||

| Long-Term Durability | ||

| Short-Term Durability | ||

| High-Definition Text, Graphics, Barcodes | ||

| Readability/Scannability | ||

| Resists Sunlight, High Temps, Chemicals, Moisture, Smudges | ||

| Shelf Life for Materials | ||

| No Ribbon Required | ||

| Indoor | ||

| Indoor and Outdoor | ||

| Scratch-Resistant Print | ||

| Wide Variety of Material Options |

This table provides a comparison of features between Thermal Transfer and Direct Thermal printing technologies.

Other label printer options: inkjet and laser

If you’ve got applications that require color or high-volume in a hurry, check out Inkjet and Laser printers. With Inkjet printing, you can customize with color, making it a favorite for signs and high-quality images. For high-speed printing, Laser printers are recommended. They provide sharp quality for text-based identification.

Whether you choose Direct Thermal, Thermal Transfer, Inkjet, or Laser, industrial printers play a key role in the identification process. Ultimately, the best printer for your business is the one that fits the type of work you do.

How Brady can help

Whether your printing needs change every day or every hour, it’s important to find a solution that makes your work easier and more efficient. With Brady’s line of high-performance industrial printers, you get both, plus Print Smart Technology that ensures:

- Easy material loading

- Auto label setup

- Reduced material waste

Your work is our work. And if it happens on-site or in a facility (or both), we offer state-of-the-art printing solutions to ensure it gets done right the first time.

Need more?

We have it. Recognizing the modern workspace as an interconnected system, Brady supports your printer with a wide variety of materials and software solutions. These innovative products are designed from real-life situations and go the extra mile to ensure you meet your goals.

If you’re looking for additional solutions, we’re here to help. Let us know a little more about your application and we’ll gladly recommend products and services that can improve your work experience.

Contact Us