Product Spotlight: Labels That Withstand Extreme Environments

Brady is continuously improving our materials, and we just enhanced this material’s top coat. The B-727 material has been replaced with B-797.

Learn more about the enhanced B-797 material and request samples.

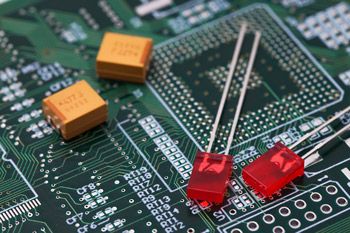

Barcode or alphanumeric identification are put to the test daily and must withstand the extreme environments of printed circuit boards or related electronic components manufacturing. These labels must withstand:

- Wave solder environments for circuit boards and electrical component pre-process labeling

- Extreme wash protocol and cleaning chemicals

- Auto apply equipment

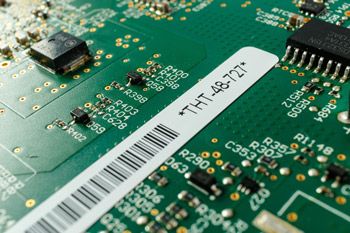

Brady B-727 glossy white THT polyimide material, created for the printed circuit board manufacturing industry, is an ultra-durable and proven to last.

Technical Data Sheet: B-727 Glossy White THT Polyimide Label Stock

Key performance attributes:

-

Abrasion resistance

Tested using Taber Abraser equipment with CS-10 grinding wheels and weighted arms. The print is still legible after 100 cycles.

-

High heat resistance

Resistance to 212°F (100°C). Labels were subjected to a range of temperatures for 1,000 hours with no visible effect, while the label remains functional.

-

Low temperature resistance

Labels subjected to -40°F and -94°F (-40°C and -70°C) for 1,000 hours with no visible effect, while the label remains functional.

-

Adhesion capabilities

Adheres to stainless steel and epoxy PC board.

Regulatory and agency approvals:

-

UL Recognized to UL969 Labeling and Marking Standard when printed with the Brady Series R6000 halogen-free ribbon

-

RoHS compliant to RoHS Directive 2011/65/EU

-

Dibutyl and dioctyl tin free

Common variations:

- Auto-Dispense: Brady B-7727 Auto-Dispensable Glossy White THT Polyimide

- Matte: Brady B-728 Matte White THT Polyimide, Brady B-729 Matte White Low Profile THT Polyimide

- Electrostatic Dissipative Gloss: Brady B-717 Glossy White THT ESD Polyimide, Brady B-718 Glossy White Low Profile THT ESD Polyimide

- Electrostatic Dissipative Matte: Brady B-719 THT Matte White Low Profile ESD Polyimide

- No re-flow required: Brady B-777 Glossy White THT Polyimide

Seeing is Believing

Request a free sample to see just how well our labels stand up to your biggest workplace challenges

Request your Sample Today