Brady Corporation’s Journey to Automation Excellence

Case Study

Brady Corporation, a global leader in safety and identification products, embarked on a two-year automation journey at their Florist Avenue manufacturing site in Milwaukee, Wisconsin, to enhance product consistency and streamline operations.

The Challenge:

The company identified the inefficiencies of offline processes, including manual data entry into their ERP system. Human involvement in data handling raised the risk of errors. Labor shortages due to global circumstances further exacerbated the issue, necessitating a solution that could standardize and simplify workflows through automation.

The Story:

To improve product consistency, Brady recognized the need to upgrade their digital infrastructure. This involved connecting manufacturing processes and implementing SCADA software. Their two-year plan aimed to achieve more effective procedures, data integrity, and increased information sharing. Brady also sought to eliminate paper-based data collection and transcribing by implementing a digital solution with barcode scanning capabilities.

The Solution:

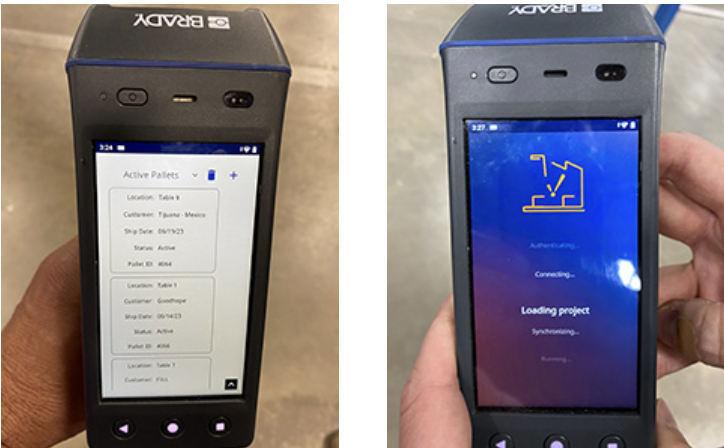

Brady adopted a progressive approach to automation. They began by building a fiber optic digital backbone across an installed base of analog machines, legacy digital equipment and modern PLCs. Then they integrated a SCADA software platform to serve as the primary user interface. Brady’s own HH83 mobile computers powered mobile data capture and interfaced directly with the SCADA system, which communicated in real time with Brady’s ERP system, ensuring data accuracy and consistency.

The Results:

Automation not only improved product consistency but also streamlined workflows and reduced errors. Step-by-step on-device work instructions ensure data consistency and simplified employee training. Brady successfully automated data capture and transmission to the ERP system using barcode labels and the Android-based HH83 Handheld Barcode Scanner, saving time and minimizing errors in the data input process. While qualitative gains were evident, quantitative results are anticipated with time.

Brady's automation journey serves as a valuable case study for manufacturers considering automation to transform their operations. It demonstrates the benefits of integrated technology in replacing error-prone manual tasks, leading to greater efficiencies. Brady intends to expand its automation efforts to further support its goal of delivering innovative, high-performance solutions in the industrial marketplace.

Brady Corporation's automation journey, driven by the need for improved product consistency and operational efficiency, showcases the transformative power of integrated technology. By embracing automation, Brady not only reduced errors and improved data accuracy but also simplified workflows, making it a valuable example for other manufacturers looking to enhance their operations.

For all the details of Brady’s Intelligent Automation success, please view our White Paper.

Download the white paperBuild your smart factory today with Brady

Let’s have a conversation to discuss what a flexible manufacturing environment can do for you.

Connect Now